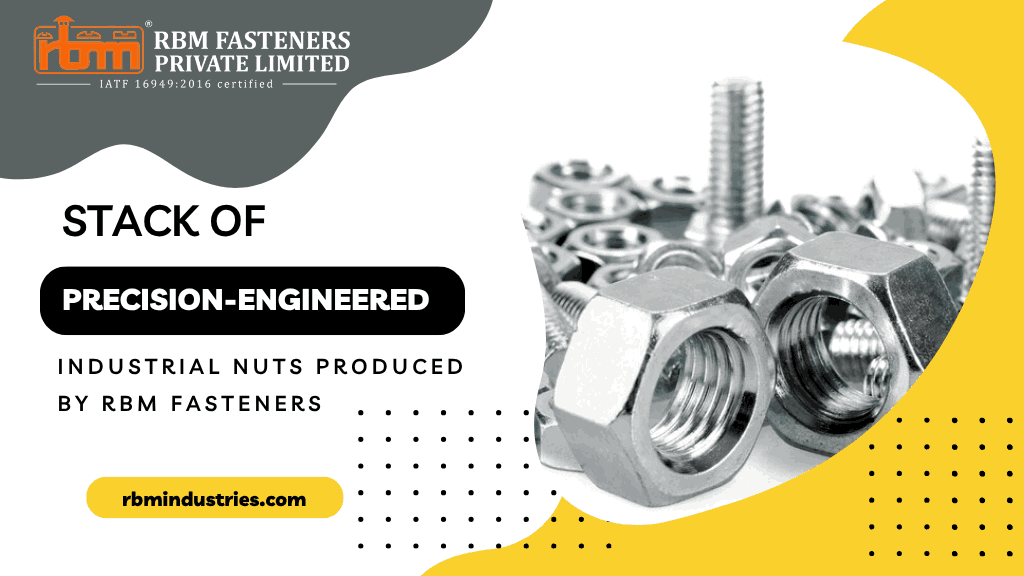

Stack of precision-engineered industrial nuts produced by RBM Fasteners Pvt Ltd

RBM Fasteners Pvt. Ltd. — Leading Industrial Nut Manufacturers in India

Introduction

In manufacturing and engineering small parts often carry significant responsibility. Nuts play a critical role in mechanical assemblies ensuring strength, durability, and precision. As a leading name in the industry, RBM Fasteners Pvt. Ltd. has earned its place as a top nut manufacturers in India. The company is known for dependable quality, an extensive product lineup, and tailored solutions for various sectors.

This blog delves into RBM Fasteners’ strengths, product offerings, production expertise, commitment to quality, and why buyers from multiple fields rely on them for their needs.

About RBM Fasteners Pvt. Ltd.

RBM Fasteners Pvt. Ltd. makes top-notch nuts, bolts, washers, and related fasteners in India. The company focuses on precise engineering and keeping its customers happy. RBM works with OEMs, distributors, and users from various fields like automotive, construction, energy, railways, and farming. They rely on advanced manufacturing strict quality checks, and tailored solutions.

An all-round product lineup built for industries

Being among India’s key producers of industrial nuts, RBM provides a wide range of products:

- Hex nuts (both metric and imperial) — includes standard heavy hex, and thin types.

- Slotted nuts (also called castellated nuts) — designed to lock using cotter pins.

- Nylon-insert (nyloc) nuts help resist vibration.

- Flange nuts offer wider bearing surfaces.

- Locking nuts include both prevailing torque types and special locknuts.

- Square nuts coupling nuts, and weld nuts suit specific assemblies.

- Custom nuts are available in unique sizes, threads, or materials upon request.

RBM supports single-line needs or supplies large multi-item BOMs.

Materials and finishes to suit all environments

RBM Fasteners knows that different applications need different materials and finishes. They provide nuts in:

- Carbon steel, which is cost-effective and durable for common uses.

- Alloy steel used when extra strength is needed.

- Stainless steel (304 316) works well to resist corrosion in industries like marine, food, or chemical production.

- Materials like brass and other non-ferrous alloys offer excellent electrical conductivity and specific protection against corrosion in demanding environments.

Available surface finishes include options such as zinc plating black oxide, phosphate, nickel plating hot-dip galvanizing, or even custom coatings. These finishes can meet needs tied to aesthetics or corrosion protection. RBM’s technical experts guide clients to select the best mix of materials and finishes to improve durability and functionality.

Manufacturing capabilities — precision at scale

RBM combines automated and manual processes to guarantee product consistency:

- Cold heading and forging for efficient mass production with superior grain flow.

- CNC machining for critical tolerances and custom parts.

- Thread rolling to increase fatigue resistance and thread integrity.

- Slotting and secondary operations for slotted/castellated nuts.

- Heat treatment facilities for hardness and strength control.

- In-line and final inspection using gauges, CMMs and calibrated tools.

These capabilities let RBM produce small precision batches and large-scale orders while maintaining quality and delivery timelines.

Quality management and certifications

Quality is the backbone of RBM Fasteners’ manufacturing ethos. They adhere to documented quality processes that include:

- Incoming raw material testing and mill certificate verification,

- Batch-wise process controls,

- Dimensional checks and hardness testing,

- Traceability via batch labels and documentation,

- Provision of test certificates and third-party inspection when required.

Compliance with recognised standards and transparent documentation help RBM’s customers meet their own regulatory and QA obligations, particularly in export markets.

Customisation and value-added services

RBM is not just a catalogue supplier — they provide engineered solutions:

- Custom dimensions and threads, including fine and metric variants,

- Special slot profiles for tailored locking mechanisms,

- Heat-treatment to customer-defined hardness levels,

- Kitting, special packaging and labelling for OEM assembly lines,

- Just-in-time delivery and vendor-managed inventory options for large clients.

These services reduce procurement complexity and support lean manufacturing practices.

Applications — where RBM’s nuts make a difference

RBM’s products are used across a wide cross-section of industries:

- Automotive & commercial vehicles — chassis, suspension, steering and drivetrain assemblies.

- Construction & infrastructure — structural joints, heavy machinery, and cranes.

- Railways & transport — vibration-prone, safety-critical fastenings.

- Agriculture — rugged, outdoor equipment requiring corrosion resistance.

- Energy & renewables — wind turbines, solar mounting structures and power plants.

- Defence & aerospace — where bespoke specifications and traceability are essential.

Sustainability and responsible manufacturing

Modern manufacturers are expected to operate responsibly. RBM Fasteners emphasises material optimisation to reduce waste, energy-efficient processes where possible, and responsible handling of chemical finishes. Their approach aligns with customer expectations for sustainable supply chains.

How to choose an industrial nut manufacturer — quick checklist

When selecting a supplier, procurement and engineering teams should confirm:

- Material traceability and available certificates.

- Manufacturing process capabilities (cold heading, thread rolling, CNC).

- Quality control procedures and willingness to allow third-party inspections.

- Range of finishes and corrosion resistance options.

- Ability to deliver custom parts and manage logistics.

- Competitive total cost of ownership, not just unit price.

RBM Fasteners meets these criteria for many partners, making them a reliable choice among industrial nut manufacturers in India.

Conclusion

Small components can have a big impact on the reliability and safety of machinery. As one of the leading industrial nut manufacturers in India, RBM Fasteners Pvt. Ltd. combines manufacturing excellence, material expertise and robust quality systems to deliver nuts that perform reliably in the most demanding applications. Whether you require standard hex nuts, specialised slotted nuts or fully custom-engineered fasteners, RBM offers the capability and customer support to be a long-term supply partner.