Assorted industrial fasteners and bolts manufactured by RBM Fasteners Pvt. Ltd.

RBM Fasteners Pvt. Ltd. — Reliable Solutions from a Top Fastener Company in India

Introduction

In manufacturing, construction and engineering, the small things often make the biggest difference. Fasteners — bolts, nuts, washers, rivets and specialised fixings — are central to structural safety, assembly efficiency and product longevity. RBM Fasteners Pvt. Ltd. has built a reputation for precision, reliability and customer-focused service, earning recognition as a Top “Fastener Company in India.” In this post we explore what sets RBM Fasteners apart, their product range, industry applications, quality practices, and why sourcing fasteners from a reputable supplier is essential for any project.

Who are RBM Fasteners Pvt. Ltd.?

RBM Fasteners Pvt. Ltd. is a specialist manufacturer and supplier of a wide range of industrial fasteners tailored for automotive, infrastructure, rail, electrical, oil & gas and general engineering sectors. Their portfolio includes standard metric and imperial items as well as customised fasteners produced to drawing, specification or proprietary designs. RBM prides itself on a customer-first approach — rapid response, material traceability and technical support that matches product supply.

Why the right fastener supplier matters

Choosing the correct fastener and a trusted supplier affects more than immediate fitment:

- Safety & reliability: the wrong material or grade can corrode or fail, causing costly downtime or accidents.

- Compatibility: precise tolerances and thread standards prevent assembly issues.

- Lifecycle cost: higher-quality fasteners reduce maintenance frequency and long-term replacement costs.

- Regulatory compliance: some sectors demand certified materials, heat treatment and test reports.

RBM addresses these areas by offering certified materials, batch traceability and testing documentation.

Product range and capabilities

RBM’s product range covers:

- Hex bolts, anchor bolts and structural bolts for construction and heavy engineering.

- Machine screws, countersunk screws and set screws for precision assemblies.

- Nuts, washers and lock-washers in varied materials and finishes.

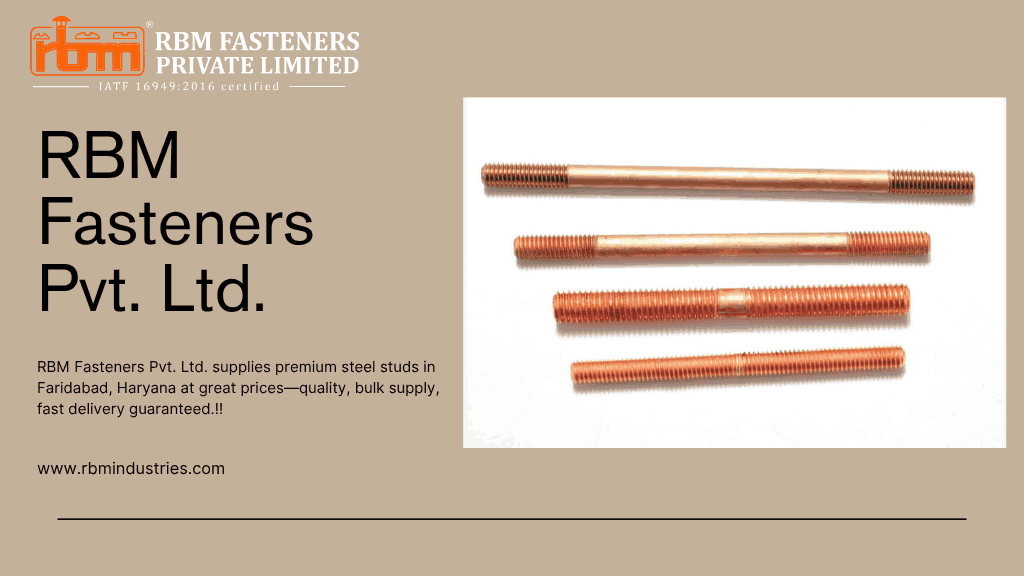

- Specialty fasteners including rivets, studs, captive fasteners and custom cold-forged parts.

- Fasteners to special standards — supplied as per IS, DIN, ASTM, BS or customer-specific drawings.

They combine in-house cold forging, threading, heat treatment and surface finishing to deliver end-to-end production.

Materials and surface finishes

RBM supplies fasteners in commonly used alloys and grades:

- Carbon steel (various grades) for general engineering.

- Alloy steels for high-strength applications.

- Stainless steels (304, 316, etc.) for corrosion resistance and hygiene-critical uses.

- Brass, aluminium and non-ferrous materials where conductivity or lightweight properties are needed.

- Surface treatments include zinc plating, galvanising, black oxide, passivation and specialised coatings for marine or chemical exposure.

Quality assurance & testing

Quality is a hallmark for any leading fastener company. RBM Fasteners implements:

- Incoming material inspection and mill test certificates.

- Dimensional checks using calibrated gauges and optical measuring systems.

- Mechanical testing including tensile, hardness, and proof load tests.

- Non-destructive testing (NDT) where required for critical components.

- Batch traceability and documentation to meet client audits and regulatory needs.

These practices ensure that each delivery meets the promised specification and performance.

Industry applications

RBM’s fasteners are used across diverse sectors:

- Automotive & transport: chassis, engine mounts, body assemblies and trim.

- Construction & infrastructure: structural bolting, precast assemblies and façade fixings.

- Energy & utilities: wind turbines, solar mounting systems, and substation equipment.

- Electrical & electronics: panel fixings, cable management and enclosures.

- Industrial machinery: gearboxes, pump assemblies, conveyors and heavy equipment.

A strong engineering team helps match fastener selection to application stresses and service environments.

Customisation and technical support

One major advantage RBM offers is the ability to manufacture custom fasteners to client drawings or to reverse-engineer proprietary parts. Services include:

- Technical consultation to specify material grades and finishes.

- Prototype manufacture and small-batch runs for validation.

- Value-engineering suggestions to reduce cost without compromising safety.

- Supply-chain solutions including kitting, just-in-time deliveries and vendor-managed inventory.

This makes RBM a partner for companies seeking more than a catalogue supplier.

Sustainability and operational excellence

As manufacturing embraces sustainability, RBM implements:

- Waste reduction through process optimisation.

- Energy-efficient manufacturing practices where possible.

- Responsible sourcing of raw materials and recycling of offcuts and scrap.

- Continuous improvement via lean manufacturing and quality systems.

These efforts reduce environmental impact and improve cost-efficiency, benefiting customers.

Choosing RBM: what customers say

Clients often highlight:

- Consistent quality across large orders.

- Responsive service for urgent or replacement needs.

- Competitive pricing coupled with technical support.

- Accurate documentation for audits and regulatory compliance.

Such feedback underscores why RBM is often cited among the Top “Fastener Company in India.”

Cost, delivery and lead times

Fastener pricing depends on material, grade, finish and quantity. RBM offers:

- Transparent quotes with material and processing breakdowns.

- Flexible MOQ options for prototype and production runs.

- Expedited production services for critical deliveries.

They balance cost and service to meet both one-off orders and long-term supply contracts.

Conclusion

Fasteners may be small, but their role in the integrity and longevity of assemblies is huge. RBM Fasteners Pvt. Ltd. combines technical expertise, comprehensive production capabilities and a customer-oriented approach, making them a dependable choice and one of the Top “Fastener Company in India.” Whether you need standard items, certified materials or bespoke fasteners manufactured to your drawing, RBM is positioned to supply quality products with the documentation and service modern industries require.

If you need product catalogues, technical datasheets or a quotation, contact RBM Fasteners for a detailed discussion tailored to your application.