High-quality industrial bushes from RBM Fasteners Pvt. Ltd.

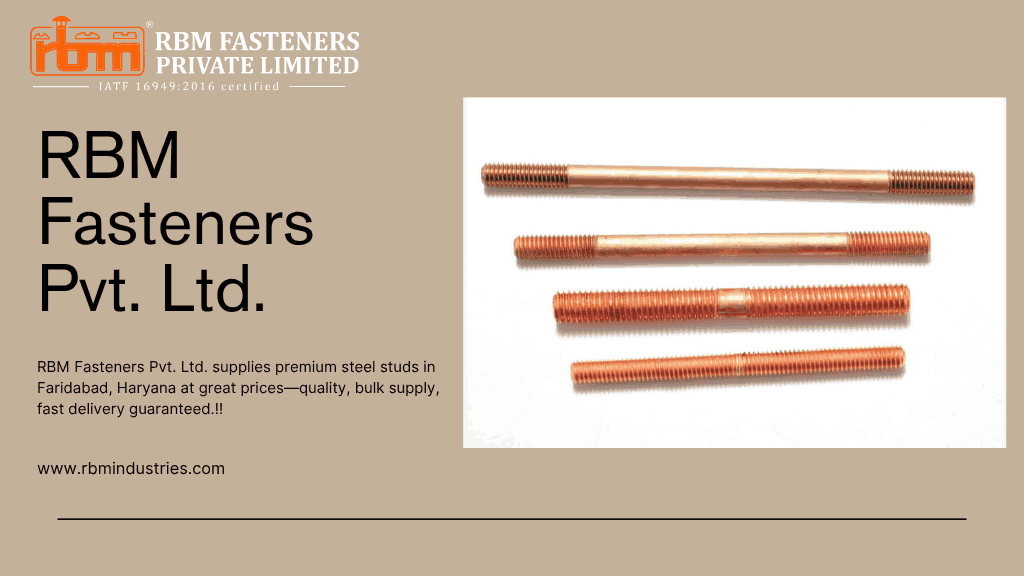

RBM Fasteners Pvt. Ltd. — Your Reliable Partner & the Best Bush Dealers in India

Introduction

Industrial assemblies, heavy machinery, automotive systems, and precision equipment all rely on small but vital components: bushes. The right bush extends equipment life, reduces maintenance costs, and improves reliability. That’s where RBM Fasteners Pvt. Ltd. steps in — a supplier dedicated to quality, consistency, and service. In this post we’ll explain what makes RBM Fasteners stand out, why they are considered the Best Bush Dealers in India, the types of bushes they supply, buyer guidance, typical applications, technical specs to look for, maintenance tips, and frequently asked questions.

Who is RBM Fasteners Pvt. Ltd.?

RBM Fasteners Pvt. Ltd. is a nationally recognized supplier of mechanical fasteners and related components. Over the years they have built a reputation for robust manufacturing standards, wide product availability, and technical support tailored to engineering teams and procurement departments. Their bush division focuses on precision manufacturing, tight tolerances, and material options designed to meet the demanding needs of industry.

Why RBM Fasteners is considered the Best Bush Dealers in India

Several factors contribute to RBM Fasteners’ leadership in the bush market:

- Wide Product Range: RBM stocks a comprehensive selection of bushes — from plain metallic bushes and bronze bushes to polymer-lined, flanged, split, and needle-bearing bushes. This broad portfolio ensures they can serve industries as diverse as automotive, construction, mining, and agriculture.

- Material Expertise: Quality starts with materials. RBM offers bushes in high-grade bronze, brass, steel (case-hardened or through-hardened), stainless steel, and engineered polymers (PTFE, Nylon, UHMW). They select materials to match load, temperature, and corrosion requirements.

- Precision Manufacturing: Dimensional accuracy and consistent tolerances are crucial. RBM uses CNC machining, strict quality control, and inspection protocols to ensure every bush meets specification.

- Custom Solutions: Off-the-shelf parts are convenient, but many applications require bespoke sizes, flanges, split designs, or special coatings. RBM provides custom fabrication and small-to-large batch manufacturing.

- Inventory & Logistics: With a smart inventory system and reliable logistics partners, RBM ensures timely deliveries across India — a key reason procurement managers repeatedly choose them as the Best Bush Dealers in India.

- Technical Support & Testing: RBM’s team assists with material selection, tolerance fits (clearance, interference), surface finish, and life-expectancy calculations. They also support small-scale testing and large QC runs.

- Competitive Pricing & Warranties: Quality and value can coexist. RBM offers competitive prices without sacrificing standards, along with clear warranty and replacement policies.

Types of Bushes Offered

RBM Fasteners supplies a diverse set of bush variants tailored for multiple use-cases:

- Plain Cylindrical Bushes: Simple, rugged, used for general bearing and alignment tasks.

- Flanged Bushes: Provide axial location and larger bearing surface — useful in housings and panels.

- Split Bushes / Two-piece Bushes: Allow installation without disassembling shafts or housings.

- Bronze & Phosphor Bronze Bushes: Widely used for sliding applications and where lubrication continuity is needed.

- Sintered (Powder Metal) Bushes: Porous structure that can be impregnated with lubricants — great for maintenance-free operations.

- Polymer-lined Bushes (PTFE, Nylon): Low friction and self-lubricating, suitable for dry running and corrosive environments.

- Needle Roller & Thrust Bushes: Designed for high radial or axial loads where compact design is necessary.

- Composite & Coated Bushes: Coatings like hard chrome, nickel, or specialized polymer layers improve wear resistance and reduce friction.

Common Applications

RBM’s bushes are used across industries:

- Automotive: Suspension pivots, steering linkages, gearbox supports.

- Manufacturing: Conveyor rollers, presses, and machine tool guideways.

- Construction & Earthmoving: Bucket pins, hinge bushings, pivot points.

- Agriculture: Harvesters, tillers, and pivot systems where dust and moisture are common.

- Marine & Offshore: Corrosion-resistant bushes for hostile saline environments.

- Energy & Heavy Industry: Turbines, generators, and rotating equipment.

How to Choose the Right Bush — Buyer’s Checklist

Selecting the correct bush requires balancing mechanical needs with environmental constraints. Use this checklist:

- Load Type (Radial / Axial / Combined): Choose a bush built to bear the expected load. Needle or roller bushes handle higher radial loads.

- Speed / RPM: High-speed applications need low-friction materials or lubricated sintered bushes.

- Temperature Range: For extreme temperatures choose appropriate metals or polymers rated for the range.

- Corrosion Exposure: Stainless steel, bronze, or coated bushes resist corrosion.

- Installation Constraints: Split bushes for retrofit installations; flanged bushes for axial location.

- Maintenance Plan: If regular lubrication isn’t feasible, choose self-lubricating (sintered or PTFE-lined) bushes.

- Tolerance & Fit: Determine whether a clearance fit or interference fit is required — RBM provides guidance and machining accuracy.

- Life Cycle & Cost: Balance higher upfront cost for longevity vs low-cost short-life options.

RBM Fasteners’ engineering team helps clients walk through the checklist to arrive at an optimized selection.

Quality Assurance & Certifications

As the Best Bush Dealers in India, RBM Fasteners adheres to industry quality systems. Their production follows ISO-based processes, material traceability, and dimensional inspection using calibrated equipment. Where required, they provide material certificates, hardness testing reports, and batch QC documentation suitable for regulated industries.

Installation & Maintenance Best Practices

- Correct Fit: Follow recommended press-fit or slip-fit tolerances; misfit can cause premature wear.

- Lubrication: Apply correct lubricant and follow relubrication intervals for greased bushes. For sintered bushes, initial impregnation is vital.

- Surface Preparation: Clean housing bores and shafts to avoid abrasion and misalignment.

- Alignment: Proper shaft alignment reduces uneven loading.

- Monitoring: Periodic inspection for wear, noise, or excessive clearance helps prevent failures. RBM can provide lifetime estimates based on operating hours and loading conditions.

Conclusion

Bushes might be small, but they are mission-critical. Choosing the right supplier can mean the difference between reliable operation and frequent downtime. RBM Fasteners Pvt. Ltd. combines technical know-how, high-quality material sourcing, precision manufacturing, and efficient logistics to earn their reputation as the Best Bush Dealers in India. Whether you need standard off-the-shelf bushes or a specialized engineered solution, RBM is well-equipped to deliver performance, longevity, and exceptional service.