Physical tests are conducted to evaluate a product’s strength, toughness, hardness, and impact resistance. These tests ensure the product can withstand real-world conditions and meet essential safety and performance requirements.

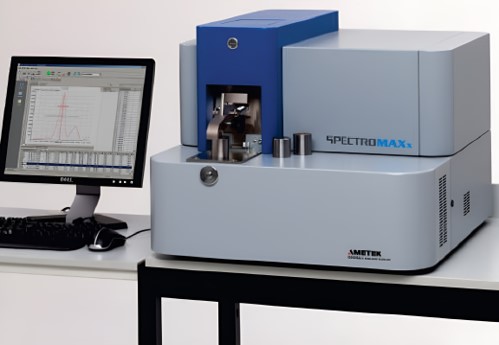

Chemical testing identifies and verifies the composition of raw materials. It ensures the correct chemical properties are present, preventing material failure and ensuring the product complies with required standards and specifications.

Metallurgical tests examine the microstructure, grain size, and heat treatment quality of metals. These insights ensure structural integrity, enhance product performance, and confirm the materials are suitable for demanding industrial applications.

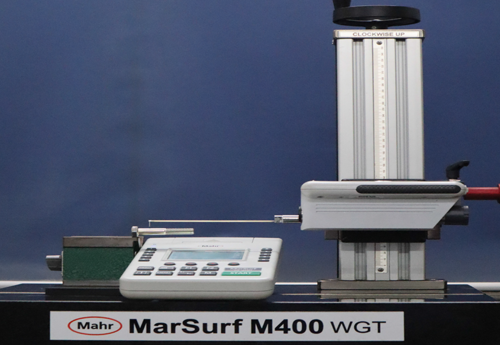

Dimensional testing ensures all measurements of a product strictly match design specifications. It verifies tolerance accuracy, shape conformity, and proper fit—critical for product functionality, compatibility, and high-precision manufacturing.